Automatic Warehouse Pallet Racking System

Product Description

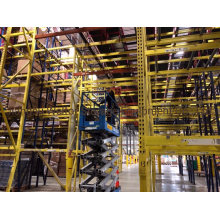

Automatic Warehouse Pallet Racking System

Automatic Warehouse Pallet Racking System

AS/RS Systems

1)AS/RS System are usually equipped with pallet racking and drive-in racking, both of which are composite structure.

2)Steel panels and wooden panels are available for loading with good capacity. Conveyors will do the loading and unloading job under the instruction from the central computer.

3)AS/RS System is mainly used in the food, tobacco, electronic, mechanical and armament industry.

Is your warehouse safe? Are your workers safe. I personally spent 3 days in a warehouse inspecting the Racks. It was the scariest place i have been in. Preventive maintenance can save lives! We inspect all equipment to ensure that they are safe and we also offer recommendations. Automated Installation Services ! We know a thing or two because we seen a thing or two.

Stacker

Structural feature:

1)Double upright structure, steady and reliable, vector frequency conversion drive and encoder position control, mechanical and electronic safety devices to ensure safe using of the system; all the way tracing technology by information transferring;

2)electric components are imported from abroad; touching screen interface for easy operation; making manual, semiautomatic, automatic and linkage control come true; used in many situations by combining with other logistics equipment.

Model | Loading Capacity (kg) | Height | Walking Speed | Remark |

DPL-0.1T | 100 | 5-30m | 160m/min | Customized based on client's requirements |

DPL-0.5T | 500 | 160m/min | ||

DPL-1T | 1000 | 160m/min | ||

DPL-2T | 2000 | 120m/min | ||

DPL-3T | 3000 | 100m/min |

Contolling System:

Communicating with WMS and ECS through OPC agreement, PROFIBUS bus network, set up by SIEMENS S7-300 controller can operate all conveyors offline, doing conveying of goods automatically.

Please refer to the attached drawing for details of conveying system.

Softwares of WMS System:

Operating system: WINDOW 2000X SEVER

Data-base: MS SQL SEVER 2000X

Warehouse management software: WMS

Equipment controlling software: ECS

Bar code management software: RFS

Other related equipment

Other related equipment include switching cart, rail cart, O/R table, automatic guided vehicle, auto-picking system, electronic label, pallet lift and so on.

Company information:

1) NANJING WELFOR Storage Equipment Co., Ltd. is one of the standard large-scale production base that specialized in the R&D, design, manufacture, install and consultation service of storage rack equipment, logistics conveyor systems.

2) The company has strong technical development efforts and product development capabilities, advanced production equipments, mature production technology and perfect quality assurance system.

3)Our company is one of the standard largescale production bases specialized in the R&D, design, manufacture, install and consultation service of storage rack equipment and logistics conveyor systems. Our company has made technical development efforts and we have product development capabilities, advanced production equipment, mature production technology and a perfect quality assurance system.

The working flow of: Automatic Warehouse Pallet Racking System

Automatic Warehouse Pallet Racking System are storage systems composed of frames and beams designed specifically for the efficient loading, sorting and storing of palleted loads. Pallets, which are simply a base made from wood or plastic, are used constantly in the transportation and shipping of products. By providing a uniform base size and shape, products can be stored more effectively.

Pallet racks take into account the size of the pallets and allow for maximum storage capacity by allowing the palleted loads to be stacked vertically and horizontally. Forklifts are often used to move and lift pallets within warehouses and loading facilities. Depending on the ceiling height of a facility, if fork lift trucks are available, pallets can be stored on high reaching racks. The desired accessibility of stored goods will affect the manner in which they are stored. Push back racks are one of the most commonly used type of pallet racking system as they are organized by depth, greatly reducing the required aisle space. The rails of the rack are slightly angled, using gravity to aid in moving the pallet loads and thus reducing the amount of energy required for loading and unloading. Other designs of pallet racking systems will differ depending on the size and shape of the pallet themselves.

Due to the nature of the operation and the typically large and heavy loads on pallets, there are important safety considerations to follow. An important consideration to take into account is the load weight of a particular item and the corresponding required structural strength of its support shelving. Overloading racks or using pallets which are damaged or broken could result in disastrous aspects. In warehouse racking, the safety of personnel working around the storage rack systems, as well as the protection against damage to goods is important. Rails and columns should be secured and made of materials which are strong enough to hold the weight of heavy loads. Further safety measures can be added in the form of Wire mesh decking or grids across the racks to increase the strength of the shelving, and to prevent objects falling down. Rollers can also be added to the racks to create rolling racks which further aid in loading and unloading ease. Pallet racks may be purchased new or used. Used racks are a cheaper alternative and for many standard pallet load sizes are more than adequate to meet storage needs. Manufacturing new pallet racks may be necessary however for spaces or loads which require unique dimensions or specifications.

OUR FACTORY

Any questions, please kindly leave us a message, we will reply you within 5 minutes from Monday to Friday, within 1 hour during weekend and holidays.

By Sunny Wang---The Sales Manager

Product Categories : Automatic Rack > AS/RS